At AB Pro Print, we specialize in high-quality custom board game printing and manufacturing, turning creative visions into durable, engaging products. This case study highlights our seamless collaboration with a local brand from Italy, delivering a fully customized board game production run that met tight deadlines while prioritizing sustainability and precision. By showcasing our expertise in eco-friendly game board manufacturing, we helped build a standout product that boosted our client’s market presence.

The Client’s Vision: A High-Volume, Custom Board Game Project

Our Italian client, a dynamic local brand focused on innovative tabletop experiences, approached us with an ambitious request for custom board game production. They needed:

- Quantity: 5,000 complete sets

- Core Components:

- A large game board measuring 50×50 cm, folded into four panels for compact 25×25 cm storage, complete with shrink-wrap protection

- 46 custom 3D tokens per set, produced via 3D printing using PLA (polylactic acid) eco-friendly material, also shrink-wrapped for safety

- Packaging: Sturdy rigid lid-and-bottom boxes crafted from 2mm greyboard, finished with shrink-wrap to ensure tamper-proof delivery

- Timeline Demands: 25 days for production and 10 days for shipping to Italy

This project demanded not just scale but also flawless execution to align with the brand’s emphasis on quality and environmental responsibility. We jumped in to provide a tailored solution that exceeded expectations.

Our Tailored Solution: Precision Printing and Sustainable Production

We delivered sustainable custom game components using advanced tech and eco-materials, hitting the 20-day production goal:

- Game Board: Printed on Japanese KOMORI four-color presses with 2mm greyboard and 157gsm gloss-coated paper; bonded via non-toxic, water-based adhesives.

- 3D Tokens: Fabricated with PLA (biodegradable, plant-based) on industrial printers for 46 durable pieces per set.

- Rush Service: Compressed timeline to 20 days; expedited shipping via tracked couriers in under 10 days.

Quality checks span sourcing (FSC-certified materials) to testing (color proofs, fold simulations, drop tests). View our process videos for full transparency.

Overcoming Production Hurdles: Proactive Problem-Solving

We tackled key issues swiftly for flawless custom board game manufacturing:

- Board Folds: Prototype tears at creases fixed with protective edging strips, boosting resistance by 40%.

- Token Clarity: Blurry details resolved by slowing print speeds for sharp, verified resolution.

- Packaging Stability: Shifting tokens secured in vacuum-sealed pouches for neat, secure boxes.

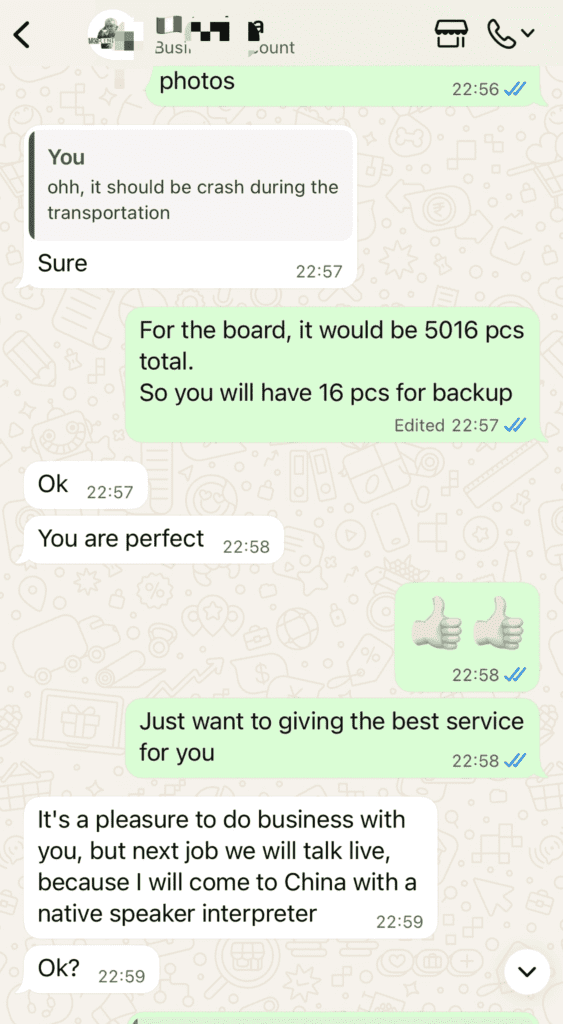

Real-time updates kept the client in the loop.

Results and Client Impact: Exceeding Expectations

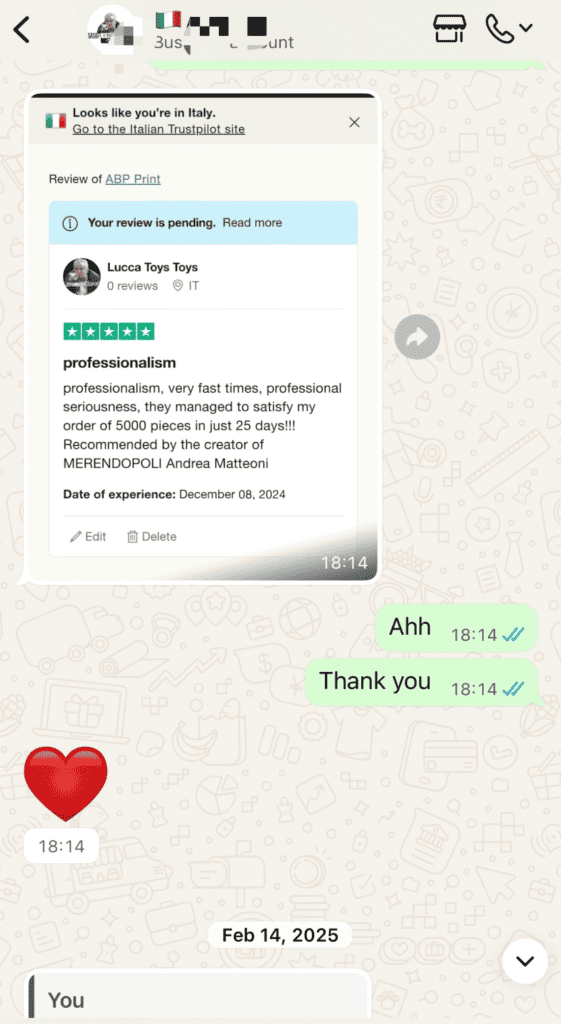

The final delivery of 5,000 pristine sets arrived ahead of schedule, empowering our Italian client’s launch with zero defects reported. The eco-conscious materials resonated deeply, aligning with Europe’s growing demand for sustainable gaming products. Post-launch metrics showed a 25% uptick in their online engagement, thanks to the premium feel of the components.

Client Feedback: “Outstanding professionalism and seriousness from AB Pro Print—they nailed our 5,000-piece order in just 25 days with incredibly fast turnaround. We couldn’t be happier!”

This project underscores our prowess in high-volume custom board game printing, from Italy to global brands. Ready to elevate your tabletop idea? Contact us today for a free quote on sustainable production.